High Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process which is used to improve or restore a component’s surface (properties or geometry). This surface engineering technique increases the lifespan of equipment by increasing erosion and wear resistance, and corrosion protection.

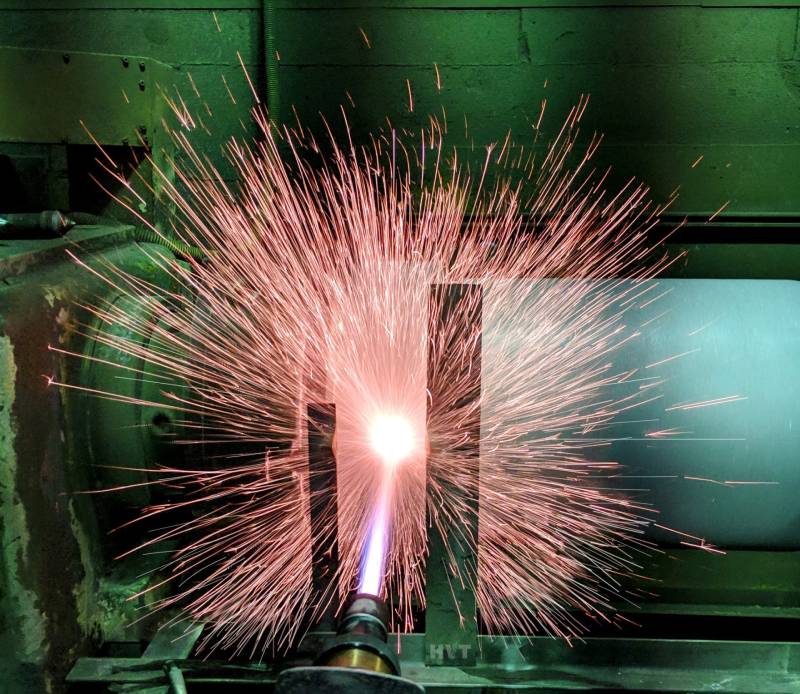

Developed in the 1980’s as a subset of thermal spraying, HVOF spraying works by mixing fluid, fuel and oxygen, that is pulled into a combustion chamber and ignited. The resultant gas has an extremely high temperature and pressure, which is ejected through a nozzle at supersonic speeds.

To this high velocity gas stream, powder is injected, which partially melts. The resulting combination of hot gas and powder is directed towards the surface to be coated. The resulting dense coating has low porosity and high bond strength providing many benefits such as corrosion resistance.

The HVOF process produces a coating that is extremely dense and well-bonded to the substrate. This makes it ideal for applications that require superior protection against abrasion and corrosion, as well as high-temperature environments.

HVOF has applications in various industries, including Oil and Gas, Industrial, Mining, Machinery and Automotive fields.

What Are the Benefits of Using a HVOF Coating?

Exceptional Hardness and Wear Resistance

HVOF coatings are known for their exceptional hardness, making them the go-to solution for industries where components face extreme wear and tear. They offer unmatched wear resistance due to a harder, tougher coating and less degradation of the carbide phases.

Versatile Material Options

HVOF coatings can be tailored to meet specific requirements by selecting from a wide range of materials. Whether it’s ceramics, metals, or carbides, these coatings can be customised to suit the needs of different applications, making them incredibly versatile. They can also be applied to a variety of substrates, including steel, stainless steel, aluminium, titanium, nickel-based alloys, ceramics or plastics.

Superior Bond Strength

The HVOF process results in coatings with superior bond strength, ensuring that they adhere firmly to the substrate material. This high bond strength not only enhances the durability of components but also contributes to improved performance overall.

Reduced Downtime and Maintenance Costs

By extending the lifespan of critical components, HVOF coatings help reduce downtime and maintenance costs. Industries no longer need to frequently replace worn-out parts, leading to significant cost savings over time.

Enhanced Performance

With the combined benefits of hardness, wear resistance, and bond strength, HVOF-coated components consistently deliver enhanced performance. Whether it’s increased efficiency in industrial machinery or improved fuel economy in automotive applications, these coatings elevate performance to new heights.

HVOF Spraying Process

The HVOF spraying process involves several steps, including:

Surface Preparation

The substrate surface is prepared by cleaning, grit blasting, and/or roughening to provide a good surface for adhesion of the coating.

Coating Material Preparation

The coating material is prepared by mixing a powdered metal or ceramic material with a binder material to form a feedstock.

Feeding of the Feedstock

The feedstock is fed into the HVOF spray gun, where it is heated and propelled towards the substrate surface using a mixture of fuel gas and oxygen.

Coating Deposition

The heated and accelerated feedstock particles impact the substrate surface, where they melt and solidify, forming a dense and well-bonded coating.

Surface Finishing

Once cooled, the coating is grinded and polished, ensuring an even and high-quality finish.

How Can We Help?

High Velocity Technologies has a combined 70 years of experience working with various industries delivering quality HVOF coatings. HVT’s HVOF spray services result in a coating that is much harder-wearing than other industry standard options. This means a longer life cycle for your components and less downtime for your machinery.

To find out more about how HVT’s HVOF technology can help your business avoid productivity loss due to equipment downtime, get in touch today!